Aspheres, spheres, fresnel lenses, cylindrical lenses

The use of aspheres can improve the imaging quality of optical systems. Aspheres are used, for example, in projection systems and also in camera lenses. Plastic aspheres can be produced much more cheaply than glass aspheres due to the forming process. In the production of plastic aspheres, it is of elementary importance to achieve a very high form accuracy and to reliably maintain it in the production process.

Free-form optics, incl. shape correction

Free-form optics offer the optical designer a great deal of design freedom when designing lighting applications or imaging optical systems. Our main focus is on the selection of the required tool concept and the adequate manufacturing strategy of the optical mould insert.

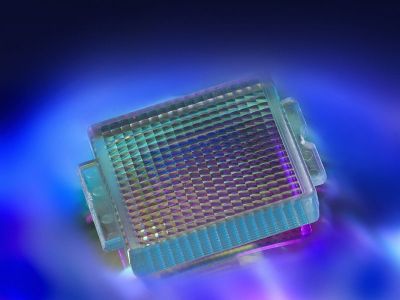

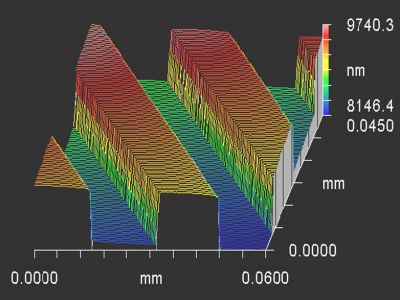

Lens arrays, microlens arrays

Lens arrays (with a large number of spherical or aspherical lens elements, arranged on one or both sides) can be used for beam homogenisation and beam shaping. However, lens arrays are also used for coupling optical light guides. Among other things, an extremely high shaping factor is important in order to keep light losses as low as possible.

Mirrors

For the production of plastic mirrors, we use thermoplastics, partly with the use of specific fillers to enable particularly dimensionally stable products. The mirroring is usually done in vacuum vapour deposition systems. The shape of the mirrors is varied: spherical, ellipsoidal, freeform, etc. Our mirrors are used in lighting systems, but also in imaging optical systems, in which case we sometimes have to meet extreme requirements in terms of shape fidelity (up to < 1µm) and surface roughness (< 2nm).

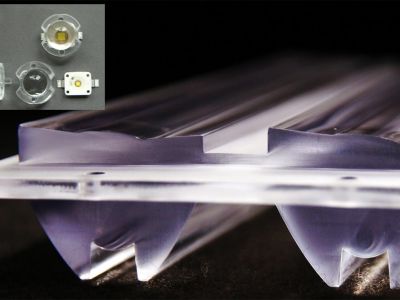

LED optics (primary and secondary optics)

We manufacture customised primary and secondary optics. The optics designer gains freedom, e.g. in terms of system performance/size, by pushing his ideas to the limit without compromise; we discuss these with him and then implement them in prototypes and series products.

Fascias, housings, etc.

A precise optical component requires secure integration into the overall system. We support our customers in the development and manufacture of mechanical components for the construction of optical systems. Examples: Housings, apertures, ferrule holders ...

Assembly group mounting, lenses

An optical system often consists of a large number of individual components. Functional adaptation of the components is an important step; adherence to an efficient optimisation strategy is important for the overall result.

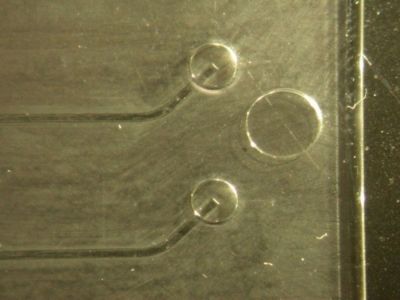

Microfluidic systems

When producing microstructures, it is often necessary not only to mould channels or fine structures but also to create functionalities, e.g. surface properties. Due to the extraordinary requirements, special processes have to be used in some cases and, if necessary, also developed on a project-specific basis. Together with our network, we support you in this task.

Lattice structures

Optical grating structures can be used in optical spectrometers or in monochromators. In some cases, the structures are also coated. We replicate grating structures and DOE (diffractive optical elements) with our know-how and also reliably form structure sizes of a few hundred nm with an aspect ratio of 1.

Hybrid surfaces

To create hybrid surfaces, we either combine macroscopic shapes and microstructured surfaces or combine different materials in one component.

Ophthalmic glasses

Lenses made of plastic with specific surface shapes, sometimes in combination with special surface structures, can be used to correct visual acuity or in AR applications (augmented reality).

Blanks (Pucks)

We have our own molds for producing blanks. The maximum dimensions are: diameter 150mm, thickness 30mm (other dimensions on request). Frequently used materials are COP, COC (Topas, Apel), OKP, PC, PA and other materials are also possible. We often have blanks made of COP, e.g. Zeonex K22R, K26R, in stock.